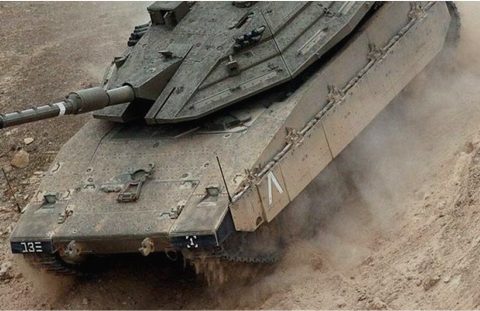

TGL works hand-in-hand with defense and military organizations around the world. The company maintains very close ties with its customers and manufactures parts and assemblies based on clear specifications. If required, our experts help customers define their needs, including materials, uses and applications. TGL develops the Merkava and Namer tank road wheel and sprockets, which was designed for extremely harsh terrains and heavy loads (in fact, the Merkava is the heaviest tank on the market due to its passive and active armor). The company also developed the road wheel rubber for the Arjun Indian tank, which was selected due to the innovative TGL technology.

In partnership with the IDF, TGL replaces the old version of the army’s APC sprockets with more advanced and sustainable units which enter into service recently. addition to products for military applications, TGL also designs and manufactures solutions for the commercial, chemical and food industries, including, among others:

-

- Hot and cold rubber coating to prevent chemical-related corrosion

-

- Coating of containers, filters, baths, funnels, barrels, wagons

-

- Rubber profiles of various sizes and shapes made in extrusion machines, including fenders, sleeves, pipes and profiles in diameters up to 400 mm

-

- Coverings for new and reconditioned rolls and drums for conveying systems

-

- Elastomer bearings for infrastructures

-

- Seals and gaskets for ABC (Atomic, Biologic, Chemical) systems

Among the company’s commercial customers are Haifa Chemicals, Israel Chemicals, Elbit Systems, Israel Electric Corporation, Israel Railways, Beit El, and more.